Original “from the factory” all chrome Cinellis are extremely rare. This little gem was originally purchased from Oscar Wastyn Cycles, in Chicago and was ridden in Minnesota. Everything is original except the chain, tires, brake pads and freewheel. More pictures HERE

1958 Cinelli Track UVI N.43 (Unione Velocipedistica Italiana)

c. 1961 Cinelli SC Road

Regrinding Bearing Races

Rare, or valuable headset (or bottom bracket) parts that are in lousy condition can be worth spending some time on to regrind. Here is a headset fork crown race from a Cinelli headset that needs help. Using a small metal lathe and a Dremel tool, I have figured out how to bring it back to life. I acquired a small mini-lathe from Harbor Freight with the sole intention of refreshing parts like this that I have traveled around the world to acquire. It’s simple in theory- lock-up the part in the lathe, and, using a Dremel tool with the appropriate grinding bit, or diamond bit, bear-down on the bearing surface as it spins to create a frsh, new, smooth surface.

Good news- it works. Bad news, it takes more work and time than I would have thought.

I used three different bits on the crown race and lower cup below. One was a round-ish green Dremel grinding bit, one was an orange torpedo-shaped Dremel grinding bit, and one was a round “diamond” cutting bit. After a surprising amount of time and effort with those bits, I finished with some sandpaper to give a slightly more smooth surface.

For these two parts, I spent about 1/2 hour. I easily could have spent another 1/2 hour making them marginally nicer. Each of the 3 bits was $5, and I probably ate through 1/3 – 1/2 of their lives, so after the $400 that I spent on the lathe, I spent $5+ on bits.

Could a guy start an enterprise regrinding parts for vintage racing parts like these? Yeah, but as much as I wish it could be done for $10 – $15 per part, and be profitable, (I’m looking for things to do in future retirement) it isn’t meant to be.

For me it makes sense because I really want the rare Cinelli and Campy headset parts for the bikes in my collection to spin smoothly, but the time and effort that I put into it is a good value to me only, probably.

Is there another way to “skin this cat”? Probably, but this is the best that I can come up with for now.

c.1960 Cinelli Super Corsa Road

Early 60’s Fred Dean Restoration

Acquisitions from Holland and Italy

1976 Colnago Super

Cinelli Chromed Steel Bars and Model 1 Stem

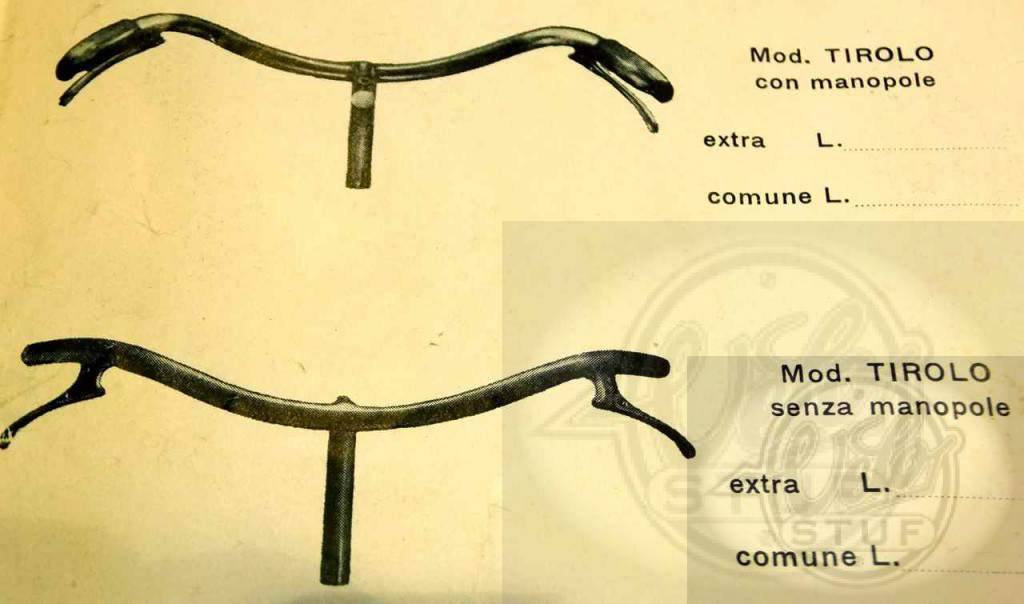

Cinelli “Tirolo” Handlebars

Cinelli “Tirolo” handlebars/stem from the 40’s-50’s.

The badge covers access to the quill bolt:

Tirolo with grips and without grips. The grips were made of bone and held in place with a screw on the underside. Rubber grips didn’t need to be held in place, so bars sold “senza manopole” did not have a screw hole in the bars: